Taking these kind of factors into consideration, therefore, requires planning and a properly-idea-out design. this means the build-out phase certainly begins when you set out to design the CNC gadget and ends whilst you subsequently placed the additives collectively. constructing a custom CNC machine from scratch can therefore take anywhere between some weeks and numerous months.

The exact period is dependent on various factors. as an instance, in case you intend to create a consumer-grade CNC device for personal use, it need to take you much less than a month – around four weeks (this time consists of the layout length). however, in case you intend to construct an business-grade CNC device that weighs extra than 3 heaps, you should anticipate to spend extra than six months. usually, the length is dependent on the elements listed below.

The main technical characteristics of the machining centers are as follows:

- The milling cutters can be differentiated by their type of teeth, cutting direction or shape.

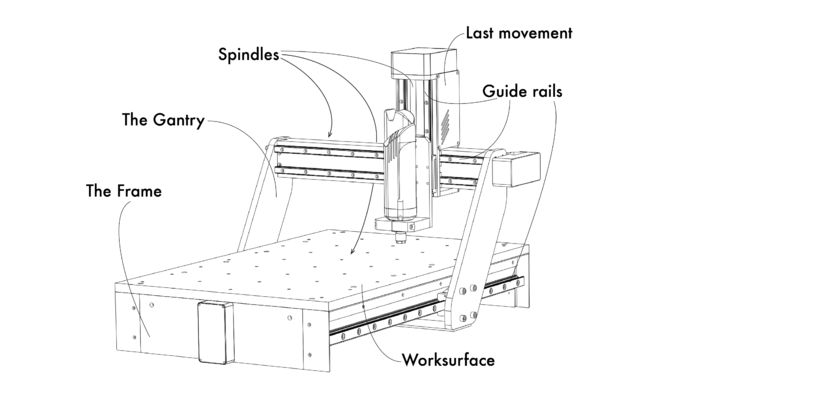

- The spindle axis may be horizontal (the z-axis is horizontal), vertical (z-axis is vertical) or universal.

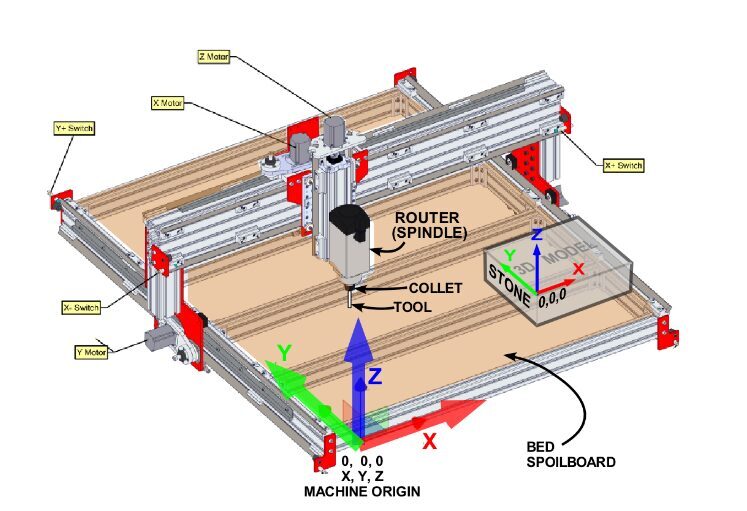

- The milling machine can have 3 axes, 4 axes (three linear axes plus one rotary table) or 5 axes (three linear axes plus 2 rotary axes).

- The production speed (this also depends on the material and the machined part).

Parts obtained: The machine allows the production of plastics or light metals (e.g. aluminum) and in s

ome cases the machining of special steels such as stainless steel. CNC machining is used in various industries like aerospace, mechanics, optics, medical, etc.

Once the prototype has been manufactured by the machine, it is necessary to perform the following operations:

Manual finishing (deburring, polishing, etc.)

Manual finishing (deburring, polishing, etc.)- Dimensional checks with the caliper.

- Checking of appearance to verify compliance with the specifications.

For more information on your CNC machining projects, we invite you to take a look at our materials a

vailable in this technology. You can also send us your project via our quote request page.