Products

PAPER CUP MACHINE

A paper cup machine is a type of machine specifically designed for creating paper cups.

These machines work by first cutting the exact shape of the paper cup using an automated cutting tool. The cutting tool is then used to shape the cup into its desired form. Additionally, the machine can be programmed to cut perforations, score lines, and other details that help keep the cups in their proper shape.

The advantages of using a paper cup machine include the ability to create uniformly shaped cups that are consistently accurate and of high quality. Additionally, the use of a machine helps reduce wastage and ensures that the paper used is used more efficiently.

These machines are ideal for any business that is looking to mass-produce paper cups of a consistent quality. Additionally, businesses can customize the cups to whatever specifications are needed. With a paper cup machine, businesses can ensure that their paper cups have a consistent quality that meets all their needs.

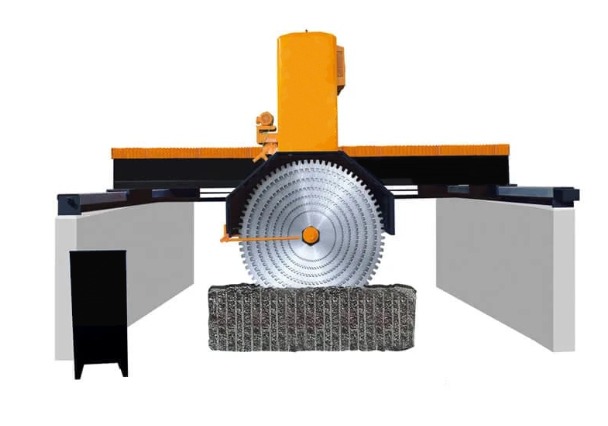

CNC Stone Cutting Machine

The cutting saws used for bridge cutting machines are usually diamond blades, which can cut both wood and marble. They are particularly useful for cutting materials that are too thick to be cut with a regular saw.

The cutting saws used for bridge cutting machines are usually diamond blades, which can cut both wood and marble. They are particularly useful for cutting materials that are too thick to be cut with a regular saw.

Automatic Pre-Stretch Stretch Film Rewinding Machine

Automatic Pre-Stretch Stretch Film Rewinding Machine is an automated machine designed to quickly and accurately rewind stretch film, ensuring that consistent and precise tension is maintained. This machine is used for a variety of applications, from food and beverage packaging to industrial applications. It is designed to be easy to use and efficient, allowing for fast and precise rewinding and tensioning of stretch film. This machine is perfect for those looking to reduce labour costs, increase efficiency, and maintain consistent high quality.

Benefits of Using Automatic Pre-Stretch Stretch Film Rewinding Machine

Automatic Pre-Stretch Stretch Film Rewinding Machine offers a variety of benefits for businesses who use it. Some of the benefits of using this machine include:

-

Increased Efficiency: This machine is designed to be fast and efficient, allowing for consistent, high-precision rewinding and tensioning of stretch film. This machine can significantly decrease labour costs, allowing for more efficient use of resources.

-

Low Maintenance: This machine is designed to be low maintenance, with minimal upkeep required. This allows for businesses to save money on repairs and maintenance, as well as making it easier to keep the machine running at peak efficiency.

-

Increased Quality: The consistent and precise tensioning provided by this machine ensures that products are protected and remain of the highest quality. This helps to ensure customer satisfaction, increasing customer retention.

Conclusion

Automatic Pre-Stretch Stretch Film Rewinding Machine is a perfect choice for businesses looking to reduce labour costs, increase efficiency, and maintain consistent high quality. This machine offers a variety of benefits, making it an ideal choice for businesses that utilize stretch film. With its low maintenance requirement and its ability to produce consistent and precise tensioning, this machine is perfect for any business looking to save time, money, and improve the quality of their products.

BRICK MAKING MACHINE

A brick making machine a device that produces bricks from various materials like clay, concrete, cement, and fly ash. These machines come in different sizes, shapes, and capacities to cater to the requirements of different businesses.

The process of brick making the raw materials with water, molding the into shape, drying and firing the bricks in a kiln. Brick making machines automate this process, making it faster and more efficient.

Some common types of brick making machines include manual, semi-automatic, and fully automatic. While manual machines require human intervention at every stage, automatic machines come with like auto-feeders, mixers and conveyors that reduce the need for human labor.

Brick making machines have revolutionized the construction industry making the production of bricks faster, cheaper, and more consistent. They have helped to reduce the environmental impact of brick production by reducing waste and using eco-friendly materials.

CNC Lathe

CNC lathes in recent times are to be had with various specific axis, permitting greater complex components to be produced without the want to manually switch machines or tools. The special axis depict the manner wherein the machined element (or the device) may be positioned / approached and circled during the machining system.

2-Axis CNC Lathe

in this fundamental set-up, the 2 linear axes may be used to perform OD/ identity (i.e. cylindrical machining) and facing operations, or drilling and tapping on the centre of the component. however, it doesn’t permit milling to be completed.

3-Axis CNC Lathe

similarly to the simple X and Z axis, C axis and life tool gadget are added. This permits the part to be positioned to carry out preferred milling operations, uninteresting, and tapping operations. Helical milling operations involving the sluggish sync rotation of the part are viable.

4-Axis CNC Lathe

right here, the Y-axis is brought to the gadget in order that off-centre machining operations can be carried out. this could work properly for more irregular and complicated operations.

5-Axis CNC Lathe

In such machines, a 2nd Turret is introduced to a three-axis CNC lathe (e.g. T2-2T). Such machines could then have 2-axis at every turret (higher and decrease turret) plus the C-axis at the rotating spindle. This permit the usage of 2 gear on the equal time at the component, as a result decreasing cycle instances extensively.

6 or more Axis CNC Lathe

right here, the permutation of such lathes may additionally encompass the subsequent:

2 x C-axis (most important and 2nd spindle)

2 x Turret (upper and decrease turret, every with 2 linear axis)

1 x Y-axis on the top turret

1 x second spindle that may flow in the direction of the principle spindle to pick out up the component

Of direction, there are machines with extra than eight axis. however, those are extraordinarily state-of-the-art and complex machines which aren’t generally wished for not unusual production needs.

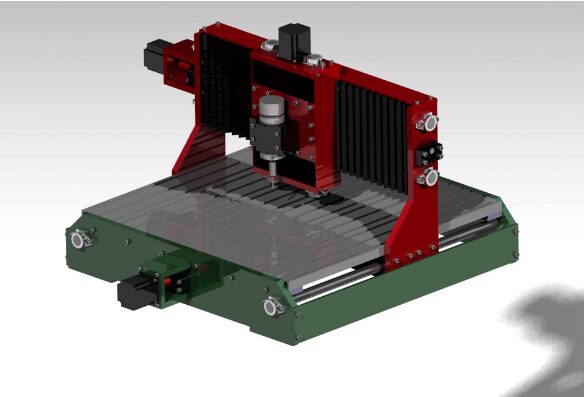

/CNC Router

/CNC Plasma Cutter